Customized Qin in 2021, template selection {YushuLinFengQin}, silk string,Fir soundboard,Catalpa wood backboard, string length tentatively 111.5cm, body length 122.5cm.

2021-01-10

Woods for Guqin making

In order to respect and maintain the timbre style of the traditional Guqin, currently the main selection materials include Chinese fir, Paulownia, Catalpa, and Spruce. For special needs, Pine, Han wood, Gold Nan, Redwood, Submerged wood, Mahogany, Sitka, etc. Valuable materials can also be used. In the process of selecting materials, the usage bias of the Qin can be derived, such as performance, collection, and commemorative use.

Guqin, which is conventionally made with standard woods, is usually used for performance and collection, and in oriental buildings, it is also custom-made into Guqin as a memorial collection of historical value because of the building materials left after at the demolition.

As for the selection of materials with different materials and density distribution, the difficulty is not only about the pitch and timbre, but more about the difficulty of processing. As for the respective stiffness coefficients of the soundboard and the backboard, they also determine the pitch of independence and whole, and more affect the final timbre of Qin.

2021-01-18

Guqin in JiaoYe form designing

Guqin form can be make by patterning design model can also follow the ancient replication. Today, we can achieve paperless design in digital drawing, and use laser-cutting to make our favorite Guqin model to make the craft up to higher level.

In the design process, it need to well know the basic structure of the Qin, and the effective length of the seven strings of the Qin and the strings distance between the head and the tail. After calculating the 13 emblem positions based on the effective string length, and begin to design the outline of the Qin body and locate the internal sound structure.

2021-01-20

Guqin in JiaoYe form cutting

The cutting form of the guqin determines the overall visual

The JiaoYe Qin cutting shape determines the overall visual appearance in a certain extent, and also highlights the most basic craftsmanship of the luther. Because in this step of the cutting process, it is necessary to have accurate composition and leave enough tolerance to prevent uncontrollable factors such as plane deviation and non-vertical sides during the cutting process.

Thanks to the convenience of modern cutting machines, the shape of the JiaoYe Qin can be cut in the most time-saving and vertical to make a natural and smooth arc that transitions across the entire body.

2021-01-29

JiaoYe Guqin’s sound hole drilling

Guqin’s Sound hole have one large and one small, one close to the end and the other closse to the middle. Its opening diameter affects the overall tone of the Guqin. Like all musical instruments and HIFI speakers, the opening diameter is directly and indirectly related to the volume of the cavity, the thickness of the plate, the dynamic volume, and the bandwidth.

If the sound hole opening too small, the tone will be too flat and restrained. If the opening too large, the tone will be loose and fluctuate too much. As for the size of the opening, the decision will be based on the experience of luthier and the fine-tuning of the final product, because it is a comprehensive judgment that combines the aesthetics of music and the changing of instruments.

2021-01-31

JiaoYe Guqin’s soundboard digging in advance

Since the shrinkage rate difference between the different wood, it will have a different internal stress under different climatic conditions. For example, when the thickness of the wood is large, the internal water saturation distribution will shrink, twist, and crack due to the difference between the inside and outside distribution.

In order to avoid series of deformations, deviation, and cracks during the Guqin making due to the big changes in the shape and structure of the wood, a certain amount of soundboard digging will be need in advance. And let it stand for a certain period of time to wait for the internal moisture distribution to be saturated and dry out in slowly.

2021-02-05

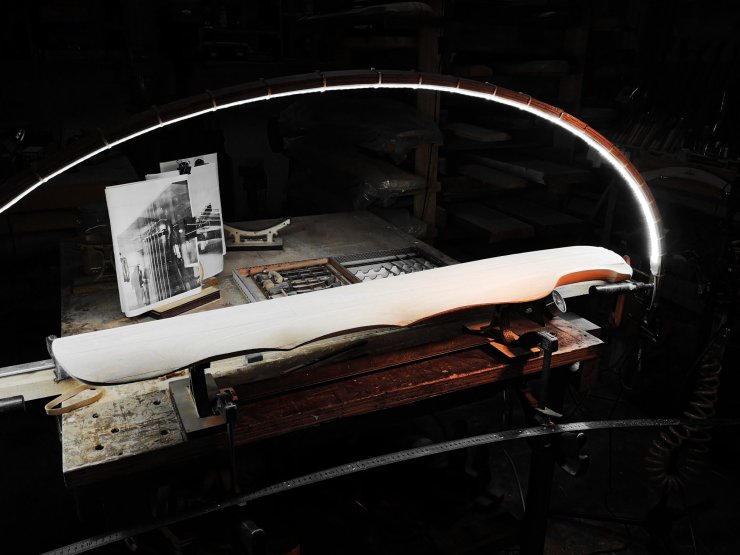

JiaoYe Guqin in JiaoYe shape template improve

The shape of the JiaoYe (banana leaf like) Guqin often requires multiple revisions before the template is made. Before the curved surface modeling, it is necessary to make a reasonable shape cutting of the piano board, so as to achieve the desired looking and feelling when shaping the curved surface.

From two-dimensional design to three-dimensional shaping, it is an aesthetic journey for light and shadow visual. The gathering and dispersion of light and shadow affects people’s judgment of the external tactile impression and temperament of things, and it is a philosophy of Yin and Yang origin from the East.

2021-02-12

JiaoYe Guqin’s wave edge design

In ancient times, the design of the JiaoYe Guqin (banana leafs like) was inspired by the abstract banana tree leaves, and its shape included the banana leaf’s wavy edge, the lotus leaf’s slim, the tortoise shells’s flanging, the snake abdomen’s plumful, and the rigid and flexible of the Guqin’s visual tension. To make Guqin with an abstract banana leaf shape, it need to have an comprehensive design from two different dimensions, two and three.

After the plane shape of the JiaoYe form cutting, the edge of the banana leaf’s wavy designed and prepare to be shape. In this step, the endpoints and volatility of each wave are planned according to the aesthetic level of the luthier and acoustic effect.

The composition of this step plans a vision of JiaoYe Guqin, and the subsequent shaping determines the true form and temperament .

2021-02-20

JiaoYe Guqin’s soundboard arc shaping

The side waves of the JiaoYe Guqin will have corresponding visual differences due to changes in the best touching of the soundboard radian.For example, the greater the soundboard radian (diameter) , the partial or overall curve visual will tend to be thin, flat, and rigid, The opposite is also the same, all need to interact and adjust through the visual and performance needs of the luthier and performers.

The preliminary shape of the soundboard arc requires a series of rigorous composition, design, and planning, using traditional techniques combined with modern equipment for preliminary and rapid modeling, then fine shape.

Traditional craftsmanship emphasizes the core essence, and we must keep it and improve it. Because modern tools bring us higher precision and lower workload, why not do it with comfortable crafting?

2021-02-24

Jiaoye Guqin’s side waves shaping

In the shaping work of the Jiaoye Guqin’s side waves , there are two key points: design and operation. The actual operation of the shaping is based on the design, and the actual shaping also requires a deep familiarity and mastery of the wood file tools.

The using skill of wood file tools just like the Chinese fencing art, it is not that “Wipe out” but “Converge” and “Converge” can contain a series of mechanics, aesthetics and philosophy. The interlocking body movements and physical lever mechanics constitute the ultimate smooth woodworking file shaping technique that you can feel, and it is also the realm of “human and sword unity” that we can see.

By using a knife or pen to materialize what you want in your heart, it is a practice, an inexplicable but macro existence the “Qi” field that we can feel.

2021-03-13

Jiaoye Guqin’s head side shaping pre-workout

If the curved part of the Guqin’s head side is more complicated, you can try to preview the shape using leftovers or flaws, so that you can predict the subsequent actual operation and explore a lots of unpredictable operating problems.

2021-03-22

Jiaoye Guqin’s head side fine shaping

The most difficult crafting part of the good-looking JiaoYe Guqin (banana leafs like) is not its skirt wave making.It makes a smooth transition with the head side, and can visually blend and coordinate the two string bearing parts of the Yueshan and ChengLu.

And behind this crafting process lies the aesthetic philosophy about visual proportions and the transition of light and shadow. Light and shadow can make us have different texture judgments of an object, just as the weight, softness, thickness, fatness and thinness of an object are all derived from our visual light and shadow and color perception.

Perhaps, the crafting technique involving temperament is already a philosophy, because this technique not only brings a completely different look and feel to an object, but also instills a sense of humanity.

2021-04-03

Jiaoye Guqin’s temperament approximate shaping

The overall temperament of the Jiaoye Qin needs to be shaping in preliminary before the Guqin’s soundboard and backboard was bonded. This is because the prototype of the Jiaoye Qin will cause deviation in the size and curve connection due to the inconsistency of the shrinkage rate of the soundboard and the backboard. In addition, tuning in the prototype of Jiaoye Qin also causes slight changes in the microcosmic, and this slight change will also cause deviation in the angle of the string surface of the Qin and adversely affect the sound.

Therefore, before the Jiaoye Qin was bonded, it can only reach to the preliminary stage of overall temperament shaping, and start to plan some accessories for the next step. The internal tuning work of the Qin cavity before and after this step is to continuously match on the basis of the control deformation and the stability of the tone. After the sound and the deformation reach a relatively stable level, the fine tuning and temperament fine shaping will be follow.

As for the physical temperament I emphasize, the most intuitive understanding is whether the woodworking shape can be made natural and smooth in the transition of light and shadow, but more importantly, whether it can reveal the delicate and refined feeling between fat and thin.

2021-04-16

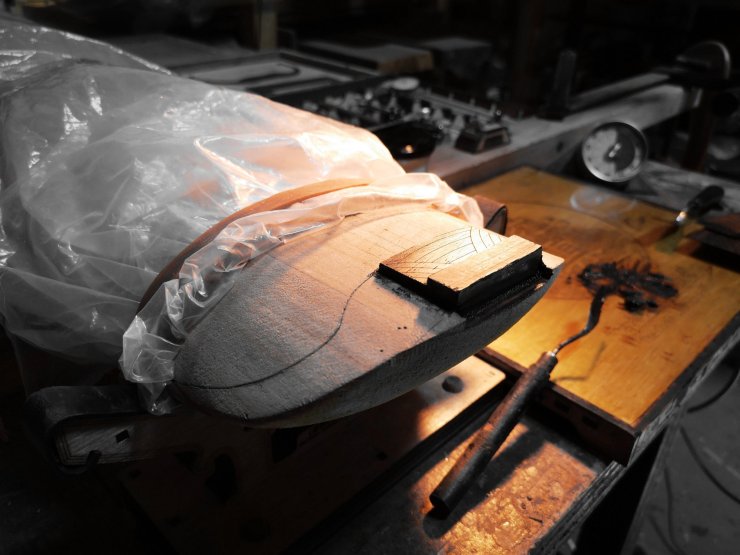

Jiaoye Qin’s Chenglu string bearing part embedding

The Yueshan and Chenglu of the Guqin are like the Violin bridge or the Guitar Nut. It bearing the tension and vibration of the strings, and the difference in thickness, volume, embed depth, density and stiffness of the Yueshan and Chenglu accessories will affect the transmission efficiency of the sounding part when the strings swinging.

Since the making of Qin’s wood workability width, texture distribution, stiffness coefficient, design or some other reasons, its head to end of the arching will thus have minor changes. Because of changes in arching of the soundboard and led to parts of the head side Yueshan’s height changes, In addition, due to the size limitation of the existing hardwood fittings and the best saving of materials, an optimal embedding depth is derived.

Therefore, it is necessary to go through a series of soundboard arching and string angle estimation before the embedding work to ensure the engraving depth of the insert slot and the insertable and reserved height of the accessories. And in this part, due to the height of the string surface in front of Yueshan and the sagging gap of the Qin’s head, which leads to different playing techniques and styles of different playing genres, and this is also one of the parts tailored to different playing genres.

2021-04-30

Jiaoye Qin’s Longyin string bearing part embedding

Guqin’s LongYin and Guanjiao is one of the important parts constitute the tail end of the Qin, but also LongYin bearing the other side of the strings swing. And its embed fit and precision directly affect the efficiency of the string swing to transmit vibration to the Qin body, and because the design and carving of the LongYin and Guanjiao will occupy a considerable proportion in the visual temperament of the entire Qin.

Guqin accessories can be cut and shaped by hardwood, or purchased and stored in a certain amount for later matching and correction, but two ways have their limitations and advantages. However, the secondary processing of the existing purchased accessories requires double check estimation and matching of accessories between the Qin body, so as to achieve considerable accuracy in the subsequent processing.

Therefore, each step in the actual operation needs to leave a certain margin for correction. Especially in the final stage of LongYin embed, whether it is perpendicular to the central axis of the Qin body and the fourth string, it is necessary to pay attention the accuracy of the line drawing, the carving flatness, the embed allowance, and the bonding sequence.

As for the embed depth and the raised Qin surface, it is estimated based on the operating experience to ensure that the cloth layer thickness, Lacquer ash thickness, and the engraving accessories can be flat with each other.

2021-05-09

Jiaoye Qin’s Yueshan embedding and string eyes drilling

Guqin’s Yueshan and Chenglu carrying the pulling force of the strings, and also one of the key parts that transmit the kinetic energy of the string to the soundboard and transfer into sound. Therefore, the thickness, density, and even the overall stiffness coefficient of Yueshan and Chenglu significantly affect the three timbres of Guqin: harmonic, open string, and stopped sound.

The Qin’s harmonic accuracy of the seven strings it depends on the verticality of Yueshan inlaid into the soundboard surface, so the string path planning and groove carving before the Yueshan and Chenglu embedding pay a highly attention to the operation accuracy.

Among them, the embedding of Yueshan and Chenglu needs to be staggered in two stages. After the embedding of Chenglu is stable after 10 days, start to file low and fix the curved surface and make it coordinate of the curvature with Qin’s head and match the whole body. Plan seven string eyes (holes) points apart from the center of Chenglu, and pull out the temporarily embedding Yueshan, then vertical drill in Chenglu, then embed the Yueshan formally.

At this stage, the embed accuracy of the main parts of the strings determines the nearly one-third of the timbre performance of the entire Qin, and it is also one of the stages with the highest accuracy requirements in the Guqin making.

2021-06-09

Preparation before tuning the JiaoYe Guqin

Due to the wavy shape of the Jiaoye Qin, the tuning work is different from the common Guqin. After the accessories are inlaid, and begin to estimate in advance the coating height that will be increased due to the cloth wrap and ash scraping, and when cutting hardwood parts later, a certain tolerance value can be reserved for the critical height.

After the Jiaoye Qin shaped, the soundboard and backboard each have a special half-wave shape after being separated. Therefore, at the beginning of the tuning stage, three stages need to be divided cleary: the pitch expect, tone fine-tunnig and the final timbre fine-tunning. And each step must reserve a fairly flexible adjustable range for the next step to be calibrated.

In short, when the accessories are available, the best and lowest natural frequency range that the Guqin soundboard can be achieved by thinning is preliminarily estimated, so as to plan the overall and partial thinning in advance.

2021-06-18

Soundboard preliminary tuning of Jiaoye Qin

According to the Jiaoye Qin’s shape and the best tone coordination, the interior of the soundboard is gradually thinned to infinitely approach to the expected pitch. The internal resonance design can basically be divided into two types: Thick middle and thin sides or thin middle and thick sides. The mixed use of the two types has derived a variety of structural forms such as high and low, half slope, waves, bamboo joint, dragon spine, honeycomb, tortoise shell, fish scale and so on.

The tuning method of Guqin is similar to the tuning of instruments such as violin and guitar in the West. Both need to adjust and match the best tone between the soundboardand the backboard. In particular, the resonant gathering area is divided into main and auxiliary part, which are called “Nayin” in the vocal structure of Guqin similar the “bass bar” in violin or guitar. The sounding design of Guqin also has a “Yinliang” similar to violin’s “soundpost” , but it depends on the tone adjustment of the soundboard, which can be according by the situation.

What needs attention is the steps and logic of Guqin tuning, first determine the corresponding shape and height of the “Nayin”, second divide the two major vibration areas of “Longchi” and “Fengzhao”, and then subdivide the respective depths of three nodes of the head and neck, the waist, and the tail. The soundboard’s whole and part settlement are based on the respective depth and thickness of the three major nodes and the transition slope.

2021-07-11

Soundboard fine tunning of the Jiaoye Qin

Under the special shape constraints of the Jiaoye Qin, the thickness distribution of the Qin soundboardl must be based on the resonance frame of the Qin, but also change accordingly in response to the complex shape of the Jiaoye Qin. A simple understand is to adjust the thickness distribution inside the soundboard cavity in response to changes the outside shape, and there are different tuning project and resonance designs inside the regular straight Qin body (but the wave shape).

In the Qin soundboard fine tuning statge, it will be different according to different Luthier’s tuning experience, timbre orientation, depth of understanding, etc. and even the various secrets tech in each genre. But all of this is inseparable from the most basic musical instrument making standards and musical theory mechanisms, and it is a comprehensive consideration of the sense of hearing.

In contrast, the Jiaoye Qin’s soundboard fine tuning can use D as its main pitches, which extends the range of tuning A=416-440Hz in response to the different tension limits of silk or steel strings. The response frequency of the sounboardl can be in the range of 69.4-76Hz or the lower 48Hz range. After the whole shape was further modified to calibrate to 71.1-73.3Hz. However, if Qin can’t be fine-tuned in outsice after the soundboard and backboard sticked, the soundboard tuning needs to increase its intermodulation offset pitch before.

2021-07-31

Backboard fine-tunning of the Jiaoye Qin’s

In the regular form (shape) of Qin sound, the soundboard uses the midrange as the main tone and the bass as the sub-tone, and the backboard uses the bass as the main tone and the mid-range as the sub-tone, blending with each other form the Qin sound that we can hear and feel. Therefore, the tuning of the backboard and the soundboard complement each other, and overall the tone is balanced with the structure of seven-string tensionwhile taking equal balance as tuning the Qin tone even the timbre.

The backboard tuning of the Jiaoye Qin’s will intermodulate according to the natural resonance frequency of the soundboard. For example, the resonance frequency of Qin across the CDFGA tone. Assuming that the panel has D and F as the main tones, the backboard can adjust the resonance frequency to about 32Hz, that is, C and A can be the main tones. In some cases, the tone of the soundboard and backboard can be interchanged or switch, and the equal loudness curve can be understood as adjusting the connection and ratio of the high and low pitch of Qin tunning.

The Jiaoye Qin can be correct in the later stage according to the tone deviation after the soundboard and backboard bonding, so it is more flexible than the regular Guqin but the operation difficulty will be slightly higher. The “Goose feet” (the endpin feet) part can also choose the slot carving in advance or later according to the tone transition of the current Qin (each of soundboard and backboard).

2021-08-10

Fine tuning and soundboard bonding of Jiaoye Qin

The tuning of the Guqin will intersect the four stages of Woodworking, Ash scraping, Lacquer coating, and Winding, so it is slightly more complicated than the guitar and violin tuning of western stringed instruments. In the Guqin tuning work, the fine-tuning of the tone needs to pay attention to its tolerance range. It is necessary to accurately adjust and retain the adjustable range for the next stage, and even the final stage of playing and storage after the guqin is completed, still continuing uninterrupted fine adjustments in accordingly.

The Jiaoye Qin tuning work is both complicate and flexible, and its wavy shape design also determines its unique tuning works. The tuning work through the three steps of Woodworking, Ash scraping, Lacquer coating. The pitch is inter-tuned countless times and is critical to the standard line.

The pitch determines the final tension performance and tone, and also ensures that the harmonic, open string, and stopped sound of seven strings on Qin can be smoothly flow. The resonance coordination and sound-vibration conversion efficiency of the Qin body determine its sound pressure, envelopment, and sound transmission distance, and it can also be sense the sound of stable, sweet, clear, and calmly while playing by later.

2021-09-25

Jiaoye Qin’s final temperament shaping

The Jiaoye Qin’s final temperament shaping is the most difficult part of how to balance the timbre with drastically change after the shaping modification. Therefore, it is necessary to consciously reserve enough margin in advance at the wood working and tuning stage for the final shaping and cloth scraping.

And to create the temperament of the Jiaoye Qin, this means the last chance to modify the shape and visual of the Qin body. The “snapshot” on the wood comes from banana leaves under the gentle spring or summer winds, which requires a long period of time to observe the growth and changes of natural plants in the four seasons of the year. In particular, how to make the thick body of the Qin looking thin and flexible, and seem the brimming with life at every angle, it requires think more from the wavy lines.

How to make the curves and arcs of the whole Qin looking smooth and natural is a long aesthetic practice. As for maintaining the appropriate aesthetic “white space” and tone accuracy in each temperament shaping, this is even more the endless cultivation of a lifetime.

2021-10-24

Jiaoye Qin’s Guanjiao re-embed

The steps of embedding and engraving the Guqin’s Guanjiao(crown angle) can be adjusted back and forth according to the making program, operation logic, and actual conditions. Since the Guanjiao is mostly designed in a step type, its operation will derive two major schemes: 1. Carry on embedding, shaping, and carving after cloth wrapping or lacquer-mixture scraping ; 2. Stepped carving on the Guanjiao after embedding, shaping, cloth wrapping and lacquer-mixture scraping.

As the previous stage planned, since the Guanjiao is positioned at the tail and close to the Longyin(the endside of string), so it has a great affect on the timbre and visuals of the Qin. The Guanjiao embedding interspersed in the process of Guqin shaping, tuning, embedding, cloth wrapping, lacquer-mixture scraping, and carving requires enough adjustment range(Tolerances and corrections).

Especially in the stage of embedding and carving the Guanjiao of the Jiaoye Qin, the curve of the Qin tail will greatly increase the difficulty of embedding. Therefore, at the beginning design of the Jiaoye Qin’s wave side, it is necessary to consider the embed depth and the thickness of the Guanjiao accessories, and it is necessary to leave sufficient adjustment range for correction at each step.

Unfortunately, when I finish this step of Guanjiao embedding, I realized that the Guanjiao design, I had mistakenly remembered the requirement that was contrary to the customer’s instructions. Fortunately, there still have corrections space for operation by following redo and correction are carried out in time. This also means that the deeper the experience, the greater mistakes made by laxity. Fortunately, there still have corrections space for operation in the previous work, and timely redo and correct are carried on. This also means that the deeper the experience, the greater the mistakes made by laxity and self-confidence.

2021-11-08

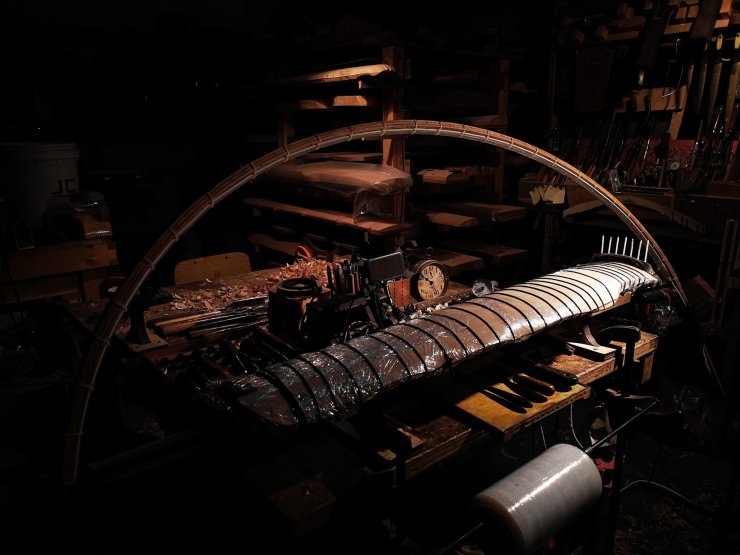

Jiaoye Qin cloth wraping

Guqin’s cloth-wrapping connects the woodwork and the lacquerwork. It is a milestone in the whole process of the Guqin crafting, and as the final version of the Guqin shape and temperament. The process of the Guqin wrapping (cloth layer) also affects the accuracy of every details by the following future, and the subsequent work will be dominated by the alternating cycle of lacquerwork and sanding-polishing.

The Guqin’s cloth-wrapping stage can be advanced or postponed according to the Guqin woodwork and tuning, and the three structural surface of the soundboard, bottomboard, and “Bianqiang”(side wall) can also be staggered and proceed independently according to experience or advantages balancing. There are three main operating schemes: 1. The whole body wrapped with cloth at the same time. 2. The soundboard(face up surface) is wrapped first, then the bottomboard 3. Only the string path is wrapped. Although the first two methods are similar, they also have their own advantages in tuning, operation, details, and accuracy.

Among them, the Jiaoye Qin is second only to the “LuoXiang Qin” in the operation difficulty of the cloth wrapping work. Due to the inherently complex poly-curved shape of Jiaoye Qin (Banana Leaf shape), the difficulty of wrapping will be greatly increased. Before the wrapping, it is necessary to plan the boundary line of Guqin and use it as the seam of the cloth edges. Reasonably stagger the wrapping time of the soundboard and the bottomboard, which can greatly reduce the potential flaws caused by blind areas, shrinkage, collision, friction and other reasons.

2021-12-25

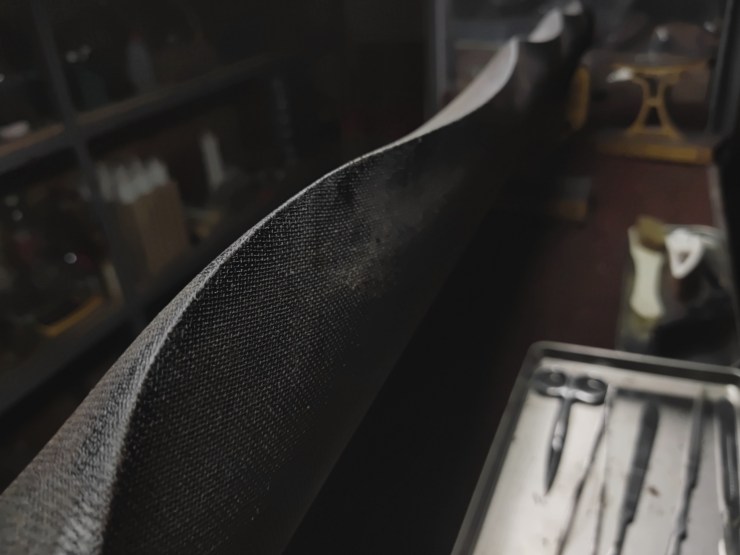

Granule scraping for Jiaoye Qin

The lacquer-mixture coating of the Guqin is used to improve the weather resistance, surface strength and touch or playing feel correction of its wooden structure. Otherwise; this step can also be used as one of the operations for reverse adjustment of the Guqin tone and timbre.

The smoothness of the lacquer-mixture layer on Qin surface is based on the uniformity of the previous cloth wrapping step and the reasonable arrangement of the actual scraping area. The lacquer mixture coating and scraping process is divided into three steps: thickness increasing of crushed particles, rough surfaces filling of medium pulverization, and smoothing fill up with lacquer-pulverization mixture. Since ancient times, its coating operations may derived from four type: brushing, scraping, pinching, and sticking.

The traditional lacquer-mixture coating and scraping operation selects antler pulverization after degreasing, degumming, crushing, and layer sieving, or adds shells, colored ores, gemstones and other mixtures of different specific density and stiffness.

The lacquer-mixture thickening coating and scraping needs to pay attention to its solid content. In addition, due to the cross-linking curing reaction of natural lacquer, it needs suitable oxygen and humidity environment. Then it is necessary to take into account the thickness increasing of particles and the conditions requirement of curing reaction during the operating process. Then the next step of calibration grinding and rough surface filling is then carried out after cures.

2022-01-21

Granule scraping for Jiaoye Qin

Although the Guqin lacquer-mixture coating is divided into three steps: granular, medium and fine, it also includes derivative work such as smoothing, forming, and patching. As mentioned the previous granule scratching stage, the coating layer almost affects one-third of the Guqin timbre, and provides enough margin for timbre and shape correction in the later stage. This process can be described as neither fast nor slow, neither difficult nor easy.

From the granular surface to be as smooth as the skin, it requires a very long coating addition and subtraction working process. It is similar to flattening the wave using calculus, adding a fixed random quantity at the base level, then average value correction, secondary increment, average value correction, tertiary increment, average value correction, and baseline correction on the reference level, until the ideal value range.

In the complete step of scraping the lacquer-mixture coating of the Jiaoye Qin, the key and difficulty lies in how to take into account the average thickness, retain details, smooth polishing, and especially the slight curved and angular details that are looming on the complex surface.

Based on this series of craftsmanship, luthier needs to master the “reverse vision”, that is, to foresee the perfection of his work and then go through the reverse process of thousands years of decay, and the key point is how to form or restore the “decay” reverse junction at the current stage. Although this philosophy of Causality, Yin Yang theory, and Im-perfectionism is difficult to comprehend, but it will always unwittingly inspired during the long journey of spiritual practice.

2022-05-20

Guqin emblem inlaying and accessory engraving

The engraving accuracy and displacement correction of the emblems(similar to the frets of Guitar ) inlay will complement the player’s performance, and even determine the pitch of the Guqin and the brightness of the harmonic to a certain extent. Because the emblems are inlaid on the curved surface, and there has a certain angle between the strings and the Guqin surface, there has a corresponding slight visual offset.

There are two main schemes for the emblem (Hui) inlay: 1. Drill holes and inlay after the Guqin’s soundboard and backboard bonding or cloth wrapping. 2. Engraving and inlaying after the Guqin fine ash or string path smoothing stage.

Then there are three kinds of positioning of the emblem (Hui) inlay scheme: 1. Be parallel to the distance of 8mm-10mm outside the first string, and drill it as the center of the circle. 2. Parallel to 7mm-8mm the outside of first string as a circle periphery for engraving. 3. Establish 2 points of first emblem and thirteen emblem outside 7mm of the first string and establish the midpoint 9-12mm outside the seventh emblem, Then three points are connected to form two straight lines and thirteen emblem center points are arranged it. As for the vertical positioning of the exact thirteen emblems, the fourth string or the average central point of the first, fourth and seventh strings is used as the vertical alignment points.

As for deviations there are usually: 1. The hanging angle between the Qin surface and the strings. 2. The oblique vision difference caused by the curved surface of the Qin body. 3. The natural bending or twisting of the Qin caused by force during the production process or after. 4. A series of positioning, dimension and sketch tolerances caused by the inlaying operation. 5. Ruler and tool maintenance and human mistakes derived from the operation process. Combining various causal details, the cumulative displacement will obviously intervene the player’s playing habits, and it also realise that a certain period of playing and running-in is required between the player and Qin in the later period.

To be continued…..

You must be logged in to post a comment.